Autosimply

- Assembly Receipt

- BILL OF MATERIALS IMPORT

- Material Issue

- MANUFACTURING ORDER

- MRP PRODUCTION PLAN FORECAST ENTRY

- PRODUCTION PLAN FORECAST ENTRY

- SHOP ENTRY

Assembly Receipt

DESCRIPTION

Creates 'Assembly Receipt' transactions.

UPDATE

Insert Only

LIMITATIONS

Serial Numbers are not supported.

The auto generation fields for lot tracking are not supported.

![]()

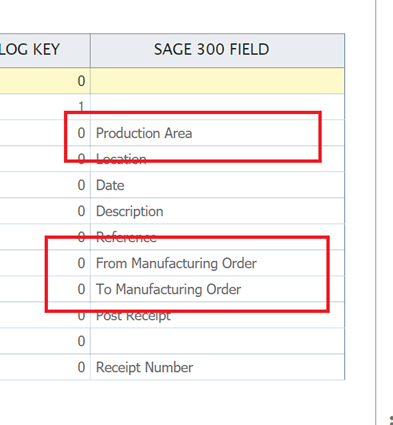

WRITEBACK FIELDS

| MF0029.ISSUENO | The Issue number |

IMPLEMENTATION NOTES

Creating a Receipt

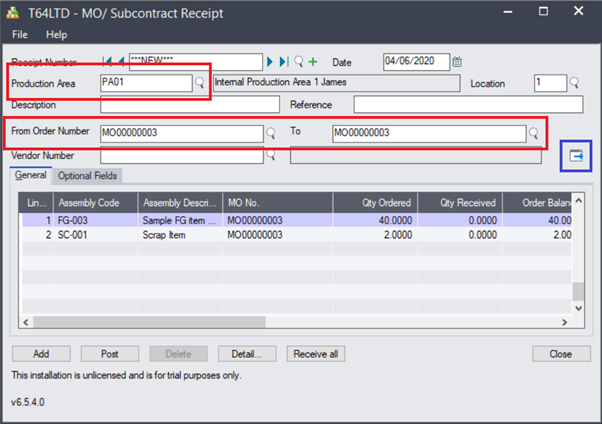

To create a receipt you must specify the Production Area and the From & To Manufacturing Order fields.

These fields map directly to the AutoSimply interface for populating the lines.

Line Matching

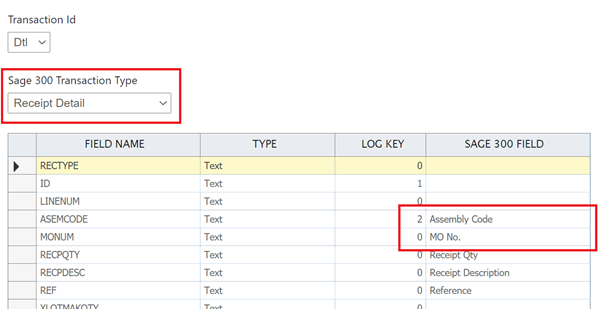

The receipt import supports two methods for matching the IMan lines to the populated receipt.

- Assembly Code - The assembly (item) code is then used to match the line to receipt.

- Item Line - This allows the line to be matched to the item line from the MO. This could either the primary product or co-product item line.

If no match can be found i.e. there is no matching Assembly in lines populated from the Manufacturing Order & Production Area parameters the line will not be included in the receipt being generated.

If the From and To Manufacturing Order parameters are a range i.e. not the same, the MO No. field on the detail will need to be populated (in addition to the Assembly Code).

Posting a Receipt

Set the Post Receipt field to True.

BILL OF MATERIALS IMPORT

DESCRIPTION

Provides the means to create or update bills or materials.

UPDATE

Insert/Update

LIMITATIONS

None

WRITEBACK FIELDS

| MF0012.LINENUM | Operation Line Number |

| MF0015.LINENUM | Component Line Number |

| MF0056.LINENUM | Co-Product Line Number |

IMPLEMENTATION NOTES

Instruction Field

Instructions are specified as a single field in the BOM Header level. To specify multiple lines, simply each line with a carriage return.

When updating a BOM, instructions will be replaced, assuming the Instruction field is mapped.

LineNumber Field

When creating Bills of Materials, it is possible to map the Line Number field to capture the auto-generated line number; this value may then be used for future updates.

Due to the underlying view implementation, it is not possible to capture the line number when updating existing BOMs, nor do all child levels support updating via the Line Number.

Updating BOMS

Header

To update an existing BOM, the following fields must be specified:

a. Item Number

b. BOM Number

c. Revision No.

If the field BOM cannot be match using the above three fields an error will be raised.

Child Record Update Logic (Operations, Components, Etc.)

Each child transaction level supports the ability to update records dependent on the keys of the record.

The BOM Import allows you to update a child record either by specifying the line number or by the ‘natural’ key such as the Operation Number or the Component ID.

For levels which use Line Numbering, updating an existing line can either be made by specifying the line number or ‘natural’ key of the record.

When updating a child record by its natural key, the update will only update the first match. If there are multiple records with the same natural key i.e. two operations with the same operation number, only the first instance will be updated.

Line Match Method

Where you wish to update a child record using its Line Number and assuming the a child level supports updating by the Line Number field set the ‘Line Match Method’ field to ‘0’.

To update using the records natural key specify a value of ‘1’.

The default update is to update by the Line Number where applicable.

Updating Records

The following table specifies how to update records/levels.

|

Level |

Natural Key |

Can Update by Line Number |

|---|---|---|

| Operation |

Operation Number (OPERNO) |

Yes |

| Resource |

Resource Code (RESRCENO) |

No |

|

Tool |

Tool Type Code (TOOLTYNO) |

No |

|

Component |

Component (COMPID) |

Yes |

| Subcontractor |

Vendor Code (Vendor) |

No |

|

Co-Product |

Co-product (CPID) |

Yes |

MANUFACTURING ORDER

DESCRIPTION

Provides the means to create and update Manufacturing Orders.

UPDATE

Insert, Update, Synchronise (see below)

LIMITATIONS

None

WRITEBACK FIELDS

| MF0012.LINENUM | Operation Line Number |

| MF0015.LINENUM | Component Line Number |

| MF0056.LINENUM | Co-Product Line Number |

IMPLEMENTATION NOTES

Instruction Field

Instructions are specified as a single field in the BOM Header level. To specify multiple lines, simply each line with a carriage return.

When updating a BOM, instructions will be replaced, assuming the Instruction field is mapped.

Sales/Purchase Order & Purchase/Sales Order Line Fields

These four fields serve as convenience fields to the respective children levels. When mapped, the values will create a single record in the linked Sales and Purchase Orders.

Both the sales/purchase order and corresponding line fields must be mapped and populated. If one of the fields is either not mapped or has a value (i.e. the order field but not the line ) no action will be performed.

The line field must have the line number as stored in the database. I.e. LINENUM and LINE fields for the Sales and Purchase Order respectively (the Autosimply UI is a little clunky in this respect).

Updating Details Lines

Updates can be made to both new MOs and existing ones.

When an order is created the details from the BOM will be copied to order exactly as if it is being created from the UI.

The following section describes how to update the lines on copied from the BOM.

Child Record Update Logic (Operations, Components, Etc.)

Each child transaction level supports the ability to update records dependent on the keys of the record.

The Manufacturer Order allows you to update a child record either by specifying the line number or by the ‘natural’ key such as the Operation Number or the Component ID.

For levels which use Line Numbering, updating an existing line can either be made by specifying the line number or ‘natural’ key of the record.

When updating a child record by its natural key, the update will only update the first match. If there are multiple records with the same natural key i.e. two operations with the same operation number, only the first instance will be updated.

- New Orders

- Since the line ids will not be known before they are saved it is only possible to update child records by their natural key.

- If an MO being created from a BOM has multiple operations with same id, it is not be possible to update the fields of the second (or any subsequent) operation. If this were a requirement it would be necessary to first create the MO and then separately update it.

- Existing Orders

- Existing orders can be updated by both the natural key and line id.

LineNumber Field

When creating Bills of Materials, it is possible to map the Line Number field to capture the auto-generated line number; this value may then be used for future updates.

Line Match Method

Where you wish to update a child record using its Line Number and assuming the a child level supports updating by the Line Number field set the ‘Line Match Method’ field to ‘0’.

To update using the records natural key specify a value of ‘1’.

The default update is to update by the Line Number where applicable.

Updating Records

|

Level |

Natural Key |

Can Update by Line Number |

|---|---|---|

| Operation |

Operation Number (OPERNO) |

Yes |

| Resource |

Resource Code (RESRCENO) |

No |

|

Tool |

Tool Type Code (TOOLTYNO) |

No |

|

Component |

Component (COMPID) |

Yes |

| Subcontractor |

Vendor Code (Vendor) |

No |

|

Co-Product |

Co-product (CPID) |

Yes |

Synchronise Update Method

When the Synchronise update method is selected updates to existing MOs will follow Synchronise deferential logic to add/delete records to child levels.

The differential logic applied in the synchronise operation is made in conjunction with the line matching logic described above.

Synchronise logic (to delete records not present in the incoming data) will be applied to each mapped level.

Those levels not mapped will be excluded from the synchronise logic i.e. will not have the differential logic applied.

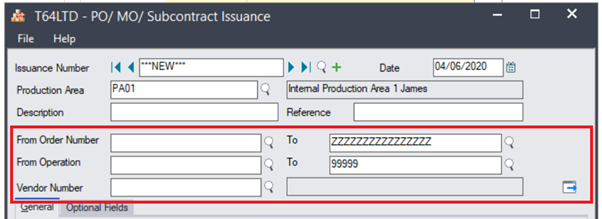

Material Issue

DESCRIPTION

Creates 'Material Issuances' transactions.

UPDATE

Insert Only

LIMITATIONS

Serial Numbers are not supported.

The auto allocation field for lot tracking is not supported.

![]()

WRITEBACK FIELDS

| MF0029.ISSUENO | The Issue number |

IMPLEMENTATION NOTES

Creating an Isssue

The parameters on the entry form are not available through the import. In order to create an issue you must specify the lines (as details).

To create a line you must specify the following fields:

- Component

- Location

- Manufacturer Number

- Operation Number

- Issue Quantity

Item Line Field

Alternatively, when the Item Line field is mapped, the corresponding line (as determined by the DETAILNUM field from the Manufacturing Order Material) will default the Component, Location and Operation Number.

The Location and Operation number can then be overridden.

Posting an Isssue

Set the Post Issue field to True.

MRP PRODUCTION PLAN FORECAST ENTRY

DESCRIPTION

Creates and deletes MRP production plan forecast entries.

UPDATE

Insert & Delete

LIMITATIONS

None

WRITEBACK FIELDS

| IP0006.LINENUM | The detail line number |

PRODUCTION PLAN FORECAST ENTRY

DESCRIPTION

Creates and deletes production plan forecast entries.

UPDATE

Insert & Delete

LIMITATIONS

None

WRITEBACK FIELDS

| PP0006.LINENUM | The detail line number |